Renewable Energy

A big problem with renewable energy sources like solar and wind power is that they are not fully controllable. For this reason, it makes sense to use batteries to store excess energy produced from these sources when they are plentiful. This blog looks at the difference between residential and commercial battery energy storage systems (BESS) and the most common circuit topologies used in each. It also suggests silicon carbide (SiC) solutions from onsemi which can bring the BESS performance to the next level.

Advantages of Having a BESS

Using on or off-grid solar inverter systems with storage batteries provides many benefits for residential and commercial users, including:

- Pricing: storing energy can reduce electricity costs by providing an alternative to a utility supplier.

- Self-sufficiency: storing energy reduces (or eliminates) dependence on a grid supply.

- Backup: stored electricity offers an alternative power source if mains power fails.

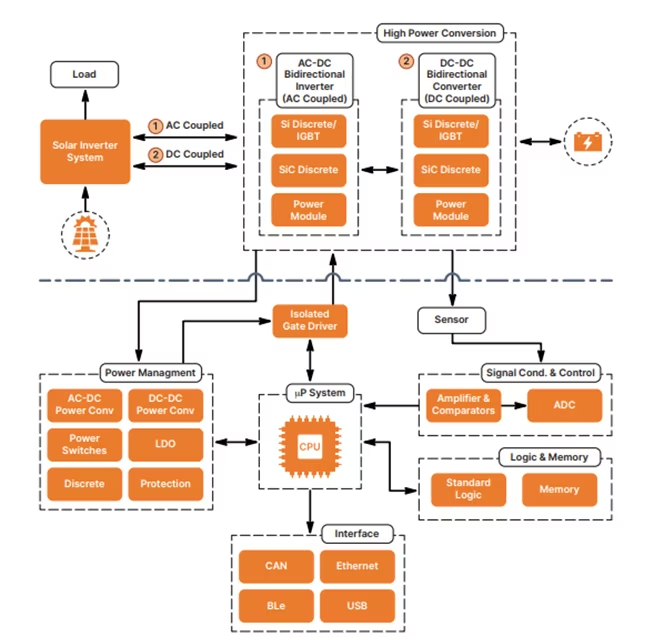

BESS Main Building Blocks

A BESS typically includes four main building blocks, including:

- Rechargeable battery module: This comprises rack-mounted battery cells with capacities ranging from 50 V to over 1000 V.

- Battery management system (BMS): The BMS protects and manages

- rechargeable batteries, ensuring they operate safely.

- Power conversion system (PCS): The PCS connects the battery pack to the grid and load

- Energy management systems (EMS): This software monitors, controls, and optimizes BESS.

Residential BESS

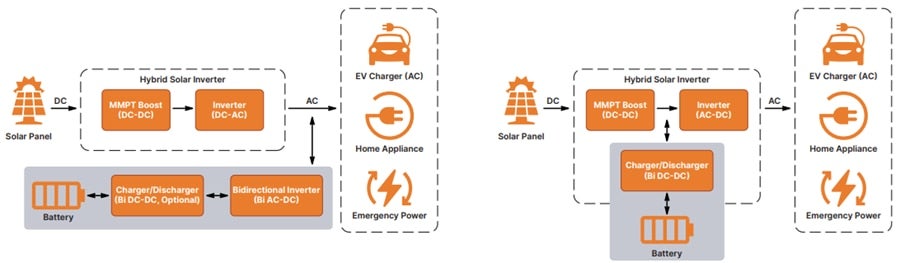

Power conversion systems used with BESS are categorized by how they couple energy (AC or DC) and power levels (residential or commercial). A DC-coupled system, or hybrid inverter, requires only one power conversion step, while AC-coupled energy storage upgrades an existing DC-coupled system.

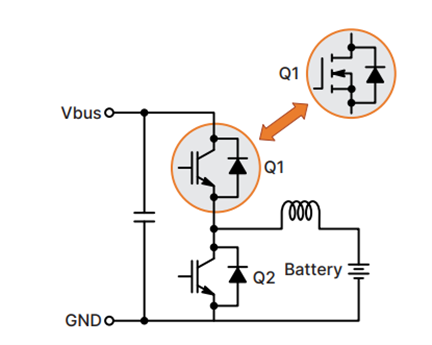

A bidirectional DC-DC converter connects a battery pack and the DC link. The bus voltage of a single-phase system is usually less than 600 V while charging and discharging power does not exceed 10 kW. A buck-boost converter is the most common bidirectional DC-DC topology because it requires fewer components and is easy to control. Two 650 V IGBTs or MOSFETs with parallel diodes like onsemi’s FGH4L75T65MQDC50 650 V FS4 IGBT (with integrated SiC diode) are perfect in a bidirectional system like this.

Isolation can ensure the safety of BESS users, and the dual active bridge converter (DAB) or CLLC topologies offer isolated bidirectional DC-DC converter solutions for BESS. For these, onsemi’s NTP5D0N15MC 150 V N-Channel Shield Gate PowerTrench MOSFET offer a good choice.

Three-phase is the standard power supply in commercial and business premises and homes with larger power demands. Power switches in three-phase applications must be able to withstand operating voltage and currents required to deliver up to 15 kW, and also a higher DC-link voltage (up to 1000 V) than that used in residential installations. This can be done using 1200 V devices, potentially in a three-level symmetric buck-boost topology.

Commercial BESS

A commercial energy storage system's input and output power range is typically between 100 kW and 2 MW. These large installations may consist of several three-phase subsystems ranging from dozens of kilowatts to over 100 kW. The DC bus voltage of standard commercial solar inverters is typically 1100 V but can be up to 1500 V in a utility-scale system.

AC-coupled systems are more common in commercial BESS because they can be easily added to an existing design. In addition, a centralized energy storage unit is much easier to install and maintain. In contrast, DC-coupled systems require are bigger and costlier to maintain because of their distributed battery banks.